Software-Defined Batteries

Energy storage is a very popular topic throughout the world today. Effective and efficient energy storage is a security issue, it is an environmental issue, and it is an economic issue. It is safe to say that this topic is important to the world at large. There is news that will bring relief to everybody who is concerned with the direction that energy storage has been taking. There is a technological solution that will make battery storage consistent and efficient. The secret is in the quality of the real time data that is being acquired from the batteries.

Traditional Battery Management System (BMS)

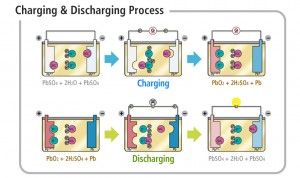

Batteries store energy using a chemical reaction. This is commonly referred to as electrochemistry. Regardless of the chemistry involved, the result is the same, electricity being converted, stored, and released.

When a battery is charging or discharging, at the basic level, we are leveraging a chemical reaction for our benefit. Understanding what occurs at every moment in that chemical reaction is critical, particularly if we are attempting to maximize something as important as the energy output of that chemical reaction. Real time data from the chemical reactions occurring in the battery will provide us with all the information we need to ensure that the battery is as efficient as it can be electrochemically.

Except there is a problem. BMSs of today do not monitor the real time chemical reactions in the battery, they monitor temperature and Voltage to determine what is occurring chemically inside the battery. The existing battery charging methodology is not done with precision, rather it is done with brute electrical force. The Current forced into the battery triggers an extreme chemical reaction in the battery that causes the overheating and damage to the battery. That heat eventually radiates out to the electrode and is detected by a sensor that determines that the battery is fully charged.

Except there is a problem. BMSs of today do not monitor the real time chemical reactions in the battery, they monitor temperature and Voltage to determine what is occurring chemically inside the battery. The existing battery charging methodology is not done with precision, rather it is done with brute electrical force. The Current forced into the battery triggers an extreme chemical reaction in the battery that causes the overheating and damage to the battery. That heat eventually radiates out to the electrode and is detected by a sensor that determines that the battery is fully charged.

Imagine filling a pint jar with a high pressure hose and determining the how filled the jug is by the overflow.

To be clear, temperature is an important metric. Batteries can fail and cause fires and the rapid rising of the temperature of a battery is a clear indicator that catastrophe is looming. However, using temperature to determine when the battery is fully charged is clearly not the best methodology. It is dangerous!

To be clear, temperature is an important metric. Batteries can fail and cause fires and the rapid rising of the temperature of a battery is a clear indicator that catastrophe is looming. However, using temperature to determine when the battery is fully charged is clearly not the best methodology. It is dangerous!

Using temperature and voltage to determine if a battery is charged is an inaccurate methodology.

Using temperature to determine what is occurring in a chemical reaction is a post hoc metric and will not provide adequate information on the battery status or life. It is fundamentally a flaw in BMSs of today and the reason for the increased level of scrutiny and additional liability on energy storage.

The Intelligent Way: Software-Defined Battery Management System (SDBMS)

The 3DFS research and development team applied our Software-Defined Power architecture to the storage environment. The results represent a titanic leap forward in battery management technologies.

By digitizing the electricity and oversampling, our system acquires a staggering 294 million data points every second. This data is analyzed and processed in real time providing a stunningly clear digital snapshot of each battery as it operates. Through real time dissaggregation of that data, we have a working chemical model for each battery in operation which allows us to maximize battery performance and lifetime.

Every battery is different. The mechanical assembly of each battery naturally is slightly different with additional variances in materials in addition to the chemistry of each battery being unique. Oversampling the electrical data of energy storage environments provides the data necessary to identify all of those unique variances and build profiles of that data over time results in customized battery management for every battery and guaranteeing optimal performance.

Every battery is different. The mechanical assembly of each battery naturally is slightly different with additional variances in materials in addition to the chemistry of each battery being unique. Oversampling the electrical data of energy storage environments provides the data necessary to identify all of those unique variances and build profiles of that data over time results in customized battery management for every battery and guaranteeing optimal performance.

We have developed proprietary models for charging and discharging batteries individually at the ideal nexus of efficiency and speed regardless of the battery chemistry type.

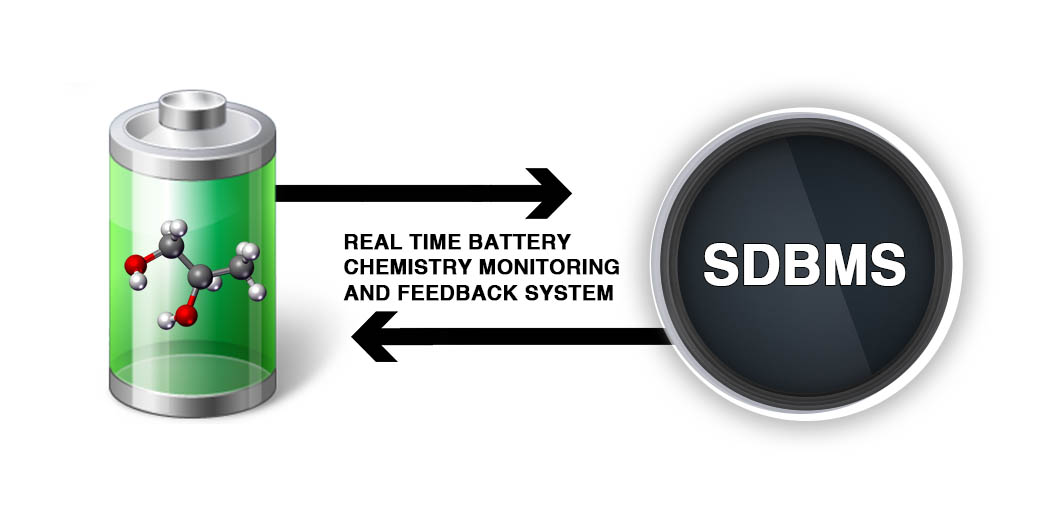

The real time battery chemistry monitoring and feedback system allows for ideal electrochemical efficiency and maximum power density for any number of batteries in a system. It individually and continuously profiles each battery pack with charging/discharging cycles, storage performance, and all testing and battery maintenance automatically driven by a comprehensive, multidimensional real time model utilizing advanced machine learning software making it perfectly customized and more accurate and efficient over time.

Our system accounts for the individual differences of each battery with specific charging/discharging cycles and proprietary battery training that assures the longest possible lifespan for the batteries, guaranteeing accurate predictive performance analytics.

The Future of Battery Management is Today

The SDBMS maximizes a battery systems performance and guarantees accuracy in the predictive performance of the batteries through real time chemical analysis and feedback for each battery.

Sitting at the nexus of Grid power, Renewables, and Demand with real time data processing gives consumers leverage with the natural ebb and flow of use and utility rate structures which can result in net zero energy homes and businesses. We can incorporate the SDBMS solution at the local level like with our existing product SineSync, or at the grid level.

To learn more about the 3DFS Software-Defined Battery Management System, contact us at power@3dfs.com.