In today’s world customers are offered an array of lighting choices. Several light bulb producers promise tempting energy savings, but beyond the higher cost of bulbs, are you getting anything beyond the promised energy savings?

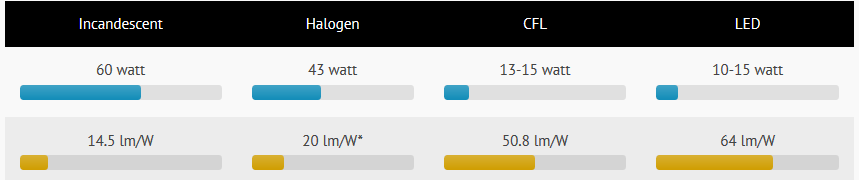

Lighting products can be broken down into three categories: incandescent, halogen, compact fluorescent (CFL), and LED. We are going to look at just the 60W or equivalent (on lumen output ≈800) and standard fixtures of each type for simplicity.

*Overall luminous efficacy of a glass halogen is 16 lm/W and 24 lm/W for a quartz halogen, so we will use the average at (16+24)/2= 20.

From what we can observe above, it seems that the best choice for an efficient light bulb would be the LED because it provides over quadruple the lumens per watt in comparison to the incandescent bulb. Most people would stop here and make the decision to choose a CFL or an LED; however, we decided to look deeper to see how far the rabbit hole goes.

The Basics:

Incandescent bulbs have been around since 1810, using a filament that’s heated to the point where it glows. The glowing filament produces the bulb’s light and a good amount of heat.

Halogen bulbs operate on the same principle as incandescent bulbs. The evaporated tungsten mostly deposits onto the inner surface of the bulb. The halogen sets up a reversible chemical reaction cycle with the tungsten evaporated from the filament. The halogen cycle keeps the bulb clean, and the light output remains almost constant throughout life of the bulb. The halogen bulb operates at significantly hotter temperatures than the incandescent bulbs.

Compact fluorescent bulbs (CFL) have an electric current and a high voltage flow between electrodes at each end of a tube containing gases. The reaction produces ultraviolet (UV) light and heat. The UV light is transformed into visible light when it strikes a phosphor coating on the inside of the bulb. The bulbs contain 3-5mg of mercury per bulb.

Light Emitting Diode (LED) bulbs use a small electrical current passing through a semiconductor material to illuminate the tiny light sources called LEDs. The heat produced is absorbed into a heat sink, keeping the bulbs cool to the touch.

Light Bulbs from the electrical network standpoint:

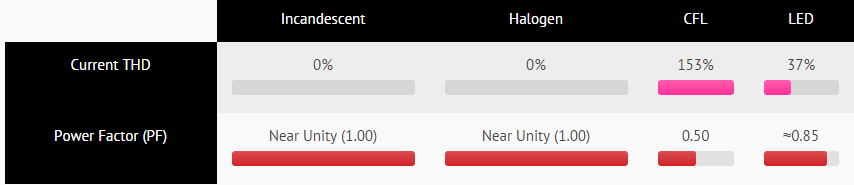

Scouring research papers that have measured the THD and PF of light bulbs was a difficult task because many of the papers were industry sponsored, so our data was sourced from independent researchers around the world. As a side note, the industry sponsored research papers’ results varied, typically favoring either CFLS or LEDs, while independent research studies were rather consistent, reinforcing our confidence in the data.

Looking at the bulbs from the electrical perspective paints a very different picture. LED and CFS are the electrical quality offenders, but what does this mean?

CFLs cause additional line losses due to low power factor. These heat losses affect the life of machines and cables; therefore, the failure rate is higher. These losses also generate additional running costs over a period of time.

LED lamps prove to be a better option because they generate less heat loss and less harmonic distortion with greater power factor. Hence these are more reliable, both in terms economics and power quality effects.

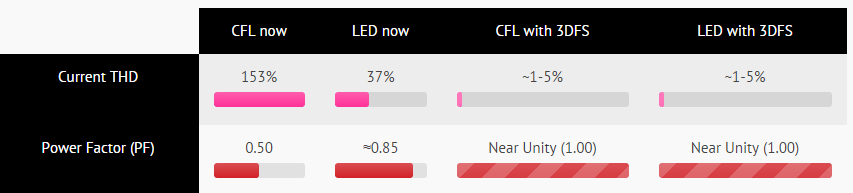

However if your facility is equipped with a 3DFS power controller, the full effectiveness of CFL and LED can be realized:

Having clean power turns electrical quality offenders such as CFL and LED bulbs to near ideal electrical quality and efficiency! With 3DFS the full potential for CFLs and LED light bulbs is realized. The customer will get all the savings and longer life, without the electrical problems.

Stay tuned as we plan on release more detailed studies, reports, and articles for the lighting industry.